LOCKOUT HASP SUPPLIER IN UAE

A lockout hasp, also known as a safety lockout hasp or simply a lockout/tagout (LOTO) hasp, is a device used in industrial settings to ensure the safety of workers during maintenance or repair activities on machinery or equipment. View our range of Safety Hasps below. A Safety Hasp can be used with a padlock, it has a slotted plate fitting over the staple which prevents its removal when locked.

It typically consists of a metal clamp with multiple loops or slots, each designed to hold a padlock. The purpose of a lockout hasp is to allow multiple workers to apply their own padlocks to the hasp, thereby securing the equipment in a locked and deactivated state. This ensures that the machinery cannot be operated until all workers have completed their tasks and removed their padlocks..

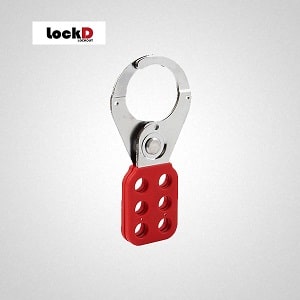

LOCKOUT SAFETY VINYL COATED LOTO HASP 38/25mmThe Lockout Safety Vinyl Coated Safety Hasp comes in four different colors. Equipped with 6 locking points for safety padlocks or locked with other hasps. This can lock out multiple workers at each lockout point and ensures that equipment remains inoperative while adjustments or repairs are carried out. Available Sizes are 25 and 38 mm . |

LOCKOUT SAFETY PLASTIC LOCKOUT HASPElectrical Dielectric Hasps enable the user to effectively attach padlocks to an energy source. Our Electrical Insulated Hasps are constructed by nylon, that will not carry a current, this means that the user doesn't have to be concerned about residual electrical energy pass down through the hasp into a technician. Can be use 6 Padlock with diameter 8 mm. |

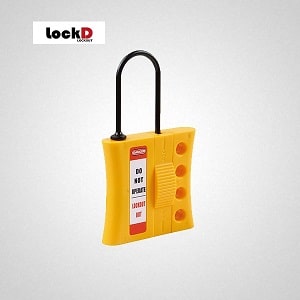

LOCKOUT SAFETY PLASTIC SLIDER LOCKOUTThe Lockout Safety Plastic Slider Lockout Hasp is constructed from spark-proof nylon materials and can be locked by up to 4 safety padlocks. Ideal for electrical applications and for use in hazardous areas. 3/6 mm Shackle thickness. Standard color is yellow. |

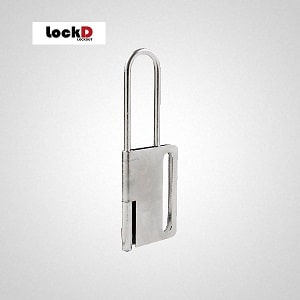

LOCKOUT SAFETY HEAVY DUTY LOCKOUT HASPThe Heavy duty butterfly steel lockout hasp can hold up to 8 padlocks and can lock out multiple workers at each lockout point. This lockout hasp can be used to ensure that equipment remains inoperative while adjustments or repairs are being carried out. It is not possible for control to be turned on until the last worker’s padlock has been removed from the hasp. |